One Flash Fault Code

Mar 25th 2022

The Propex heaters are designed to be a safe and reliable source of heat for your vehicle. Being mounted in a non-stationary vehicle presents challenges as the units are subject to vibration and exposure to all types of environments. Because of this, Propex designers err on the side of caution and create distinct operating parameters for the heating units. If the heater's electronic protection system senses that the unit is outside safe operating parameters, it will show a fault code and shut down for inspection.

This article is for the one flash code. If your thermostat is continually flashing a single flash between pauses, this is for you.

Below is from the thermostat handbook that comes with your Propex unit.

Number of Flashes - 1

Fault - Flame Failure

Remedy - Check gas supply making sure there is gas in the bottle and no blockage in the gas line. Ensure propane is used at temperatures below +5 degrees C. Clear lockout as described.

Here is a video of what the one flash code will look like on your thermostat. Please note that the cadence will be the same regardless if you have an analog or digital thermostat.

1 Flash Code on a Propex Heater

Step One

The first thing to do is reset your unit from the thermostat. You can review that procedure below.

Resetting A Propex Digital Thermostat

Resetting Propex Analog Thermostat

If the one flash code comes back, proceed to step two.

Step Two

Confirm your propane tank is open. Most propane tanks have an on/off valve on the tank and, if it is closed, propane will be unable to flow to your unit.

Step Three

Make sure you have propane in your tank. This is usually done with a gauge directly off the propane tank. Don't rely on the weight of your tank or on the last time you filled up your tank. We have also come across gauges that have either failed or read incorrectly, so be sure your gauge is good.

Step Four

Confirm that you do not have any obstructions on the fitting attached to the back of the unit or on any other of your fitting in the propane supply line. We have seen thread tape or a similar gasket maker covering the propane inlet when the fitting was installed.

Step Five

Check your regulator! Regulators cause 95% of all one-flash codes, please do not overlook this step.

Confirm you have a high-quality two-stage regulator. Single-stage regulators or low-quality regulators have inconsistent or fluctuating pressure, and this will cause the unit to throw a one-fault code.

Confirm your regulator is set between 11.5" - 12" of water column.

Please Note: Most off-the-shelf regulators will say they are set to a specific water column, but with any mass-produced product, there is room for variation. For example, the regulators we purchase are said to be set to 11.5" water column, but when we test them they are anywhere between 10"-15" inches. We manually re-calibrate every single one before we put them on the shelf to sell. The only way to confirm your regulator's pressure is to either purchase our pre-calibrated regulator or check yours with a manometer.

Video of how to test your regulator.

Step Six

Confirm all your propane supply lines are free of blockage and there are no kinks in the lines. An easy way to test this is to turn your propane tank off, disconnect all your lines from your tank and appliances, and blow compressed air through the lines. If you hear air coming through the other side, your line is free of obstruction. Another way to confirm your lines are free is to tee in a pressure gauge right before the Propex. That way we know the unit is indeed getting fuel.

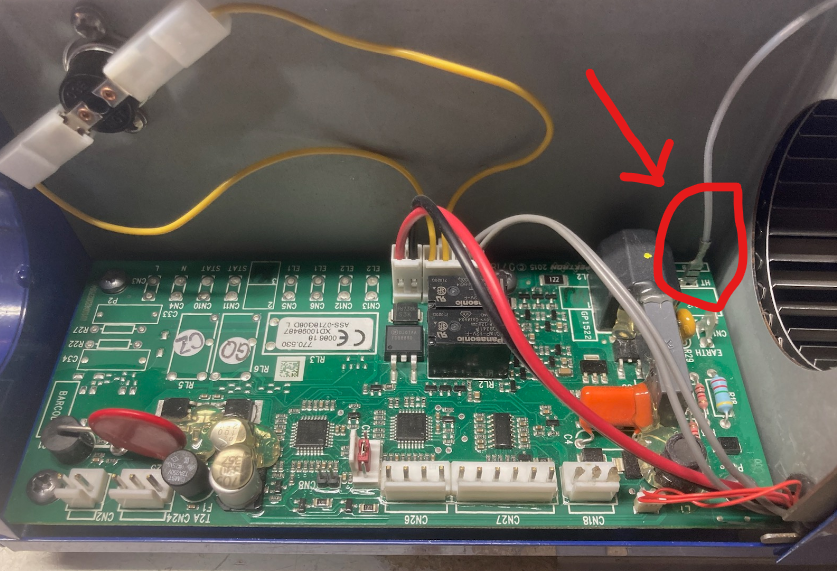

The picture above is from our repair bench and there is a flow of propane being burned by the Propex heater.

Step Seven

Ignitor Problems - Igniters are misaligned or incorrectly gapped.

Inside the unit, there are two small electric igniters that light the propane in the combustion chamber. Two small electrodes make a spark as the heater receives propane and attempts to ignite. If they are misaligned, not gapped to 3mm, or faulty the unit will not light.

Listen for the clicking

Hold your ear 4 inches away from the exhaust pipe that comes out the bottom of the unit. This is a stainless steel flexible tube and it should be routed out the side of your rig. In proper working order, you should hear a rapid burst of clicks and a wooshing sound indicating the unit has begun burning fuel.

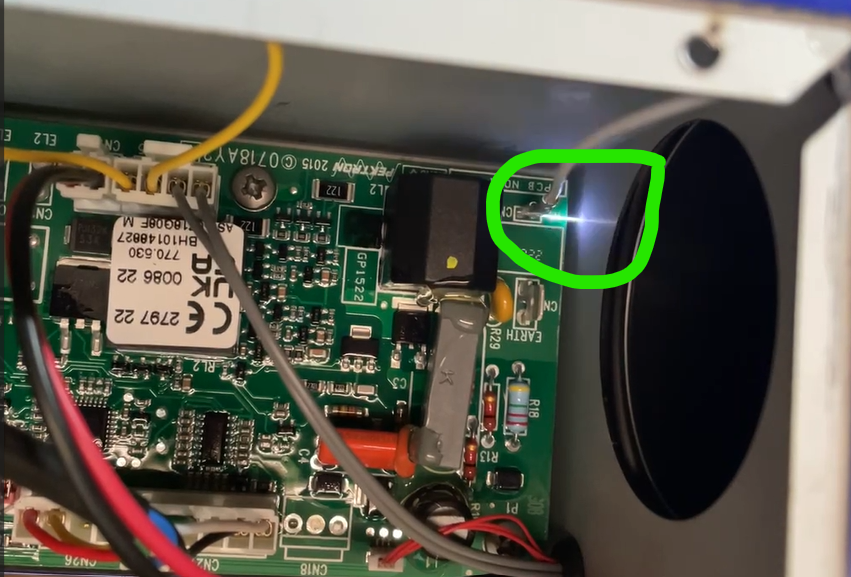

If the igniters are misaligned causing a large gap between them, the spark will either not be powerful enough to light the propane entering into the combustion chamber, or the spark will arc in the wrong spot. This normally happens on the fan blade case because this is the closest ground. (picture below). When you are hearing the clicks look here to see if you have an arc. If you see this, the unit will need to be sent in for servicing.

If the igniter is faulty, you will also hear the clicking, but you will not hear the wooshing sound. This cycle will repeat multiple times before giving you a flame failure fault. If you are hearing a series of clicks, but the unit does not ignite, you will need to send the unit in for servicing.

The HS2000 & HS2800 igniters are NOT self serviceable. DO NOT attempt to open the Propex to fix your igniters. Doing so will damage your heater, and it will not work properly after the case is open.

If you have a HS2211, the ignitor can checked and replaced without sending it in for service. The igniters are behind the plate that holds the gas valve where the propane enters the heater. Please read the HS2211 Ignitor Gap Reset article.

Step Eight

Failed Main Circuit Board

Hold your ear 4in away from the exhaust pipe that comes out the bottom of the unit. This is a stainless steel flexible tube and it should be routed out the side of your rig. If you do not hear a rapid series of click's make sure your igniter leads have a good connection to the circuit board.

If this connection is solid and you still do not hear any clicks your circuit board is likely bad and it will need to be replaced.